- Home

- /

- Custom Engineering

- /

- UV RIM Coating

UV RIM Coating

UVio has worldwide experience of producing innovative UV curing solutions for the Beverage Can industry. In particular, UVio has expertise in Bottom Rim Coating – where protective coatings are applied to the bottom rim of both steel and aluminium beverage cans.

Benefits of Bottom Rim Coating

- For Steel: to protect the Can from corrosion after it leaves the Canmaker until it reaches the consumer.

- For Aluminium: to improve Can mobility and production efficiency through the manufacturing and filling lines.

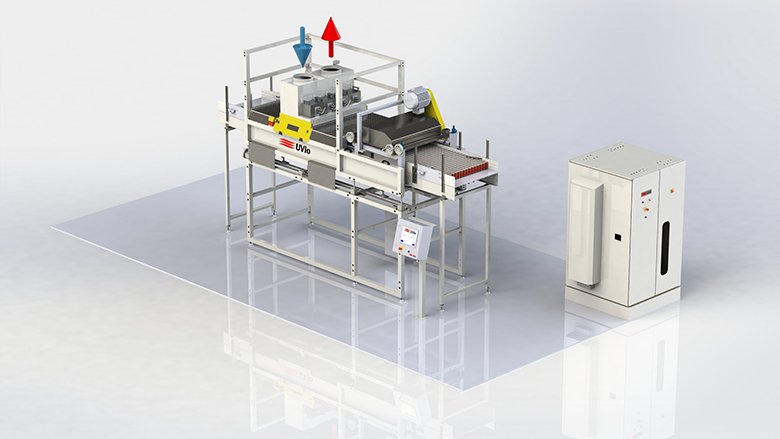

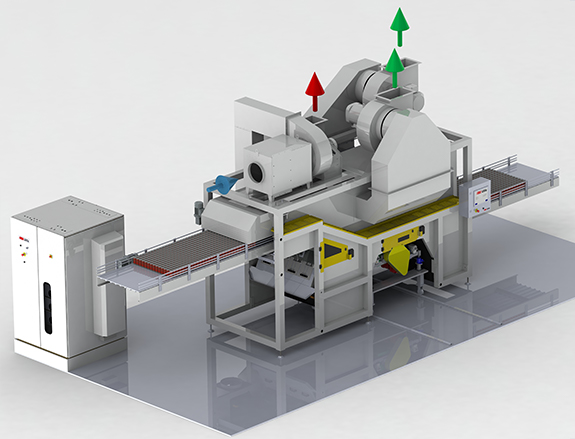

UVio offers a range of options from individual component supply to fully integrated systems with air-conditioned control cabinets and standalone machine controls, including everything from coating tanks to conveyors.

Integrated Mass Rim Coat Systems:

Our experience of installing Excelitas Noblelight UV systems into Beverage Can lines has led to our latest innovation: the Integrated Mass Rim Coater (IMRC) system. This system has been designed to optimise ease of use and minimise cost of ownership.

Market leading Core Technologies

- Rim Coaters: Gerhard’s range of metering roll applicators and coating delivery systems offer unrivalled adjustability and durability.

- UV Lamps: Excelitas Noblelight’s UV lamp systems have led the way for this application for many years, with the LH10 Mark II System being the latest innovation.

To find out more about the unique features of the UVio IMRC please Contact Us